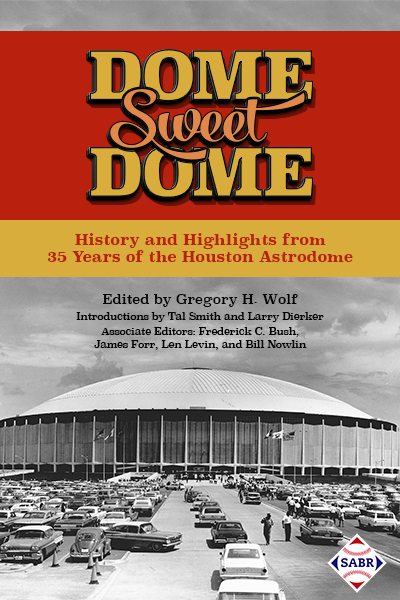

Houston Astrodome: Engineering the Eighth Wonder of the World

This article was written by Kenneth Womack

This article was published in Dome Sweet Dome: History and Highlights from 35 Years of the Houston Astrodome

In order to bring the Astrodome to fruition, given the project’s incredible size and scope, Roy Hofheinz consulted with many of the leading architectural and engineering minds of his era. He was particularly concerned with making his original vision of a modern-day Roman Colosseum a reality.

In order to bring the Astrodome to fruition, given the project’s incredible size and scope, Roy Hofheinz consulted with many of the leading architectural and engineering minds of his era. He was particularly concerned with making his original vision of a modern-day Roman Colosseum a reality.

The processes associated with the design and eventual construction of the Dome’s revolutionary roof structure began in early 1962, with principal architect Robert Minchew’s rendering of the stadium having been completed. At this juncture, the responsibility for engineering the Astrodome’s roof and supporting structural edifices became the province of Walter P. Moore and Associates. Over the years, Moore and Kenneth E. Zimmerman would serve as the engineering minds behind a host of Houston area landmarks, including the Jesse H. Jones Hall for the Performing Arts, Rice Stadium, the Warwick Hotel, the Bates-Freeman Building at the University of Texas M.D. Anderson Cancer Center, and St. Vincent de Paul Catholic Church, among others.1

But the Astrodome would always be Walter P. Moore and Associates’ crowning achievement. After prevailing bond issues were resolved via the election of January 31, 1961, Moore and Zimmerman were formally allowed to begin the vital work of designing and testing their plans for implementing a roof structure that was capable of withstanding seismic shifts and gale-force winds, as well as the forces of time. On February 2 excavation of the site began promptly when a “huge dragline ripped dirt from a 300-acre site off S. Main.”2 Within a matter of weeks, some 260,000 cubic yards of dirt had been removed from the site in order to accommodate a mile-long drainage ditch and the building’s sublevel playing field. Construction would be delayed until 1963, due to a series of post-bond legal, financial, and political challenges. The new timetable meant that the Dome would be ready in time for the 1965 major-league season.3

In the interim, teams of engineers and architects had already begun honing and testing the final design specifications for the structure. Given their background in long-span structures, Moore and Zimmerman had been carrying out the technical analysis for the project since 1960. At one point they considered Buckminster Fuller’s famous Geodesic Dome designs, while also exploring the notion of wood trusses to support the roof structure. Ultimately, steel was selected, given its much higher tensile strength, in order to carry the massive load. A lamella roof structure, proposed by Roof Structures, Inc., headquartered in Webster Groves, Missouri, was chosen because of its spider-web network of trusses. The lamella structure involves a double layer of steel members to ensure the building’s engineering integrity.4

With Roof Structures, Inc., led by G.R. Kiewitt and Louis Bass, in tow, the project shifted to the testing phase in order to ascertain what kind of loads could be hung from and supported by the Dome’s eventual roof design. The construction specifications stipulated that the roof be able to handle a live load of 15 pounds per square foot; a sonic boom loading of 2 pounds per square foot; and a wind load of 40 pounds per square foot or sustained wind velocities of 135 MPH with gusts of 165 MPH.5 Given the emergence of supersonic jet technology, the issue of being able to withstand a sonic boom was believed to be a key issue in building construction during the late 1950s and 1960s. When supersonic jets like Chuck Yeager’s Bell X-1 and the former British Airways/Air France Concorde broke the sound barrier, a boom and resulting shockwave was created. During the early 1960s, a 2-pounds-per-square-foot load was considered to be acceptable at the time, although Roof Structures prepared the building for an additional 2 pounds per square foot – or the possibility of two consecutive sonic booms – as an allowance.6

Perhaps even more significantly, the Dome’s roof had to be able to withstand hurricane-force winds, given the building’s proximity to the Gulf of Mexico and its annual assaults during the Atlantic hurricane season. For this reason, Roof Structures showed particular concern for the phenomenon of uplift in terms of high wind-resistant construction necessitated by projects such as the Astrodome. In such cases, uplift forces must be transferred down toward the foundation in order to prevent catastrophic damage associated with the powerful suction associated with hurricanes. In order to properly calibrate the design, Roof Structures conducted wind-tunnel tests in an effort to establish the kinds of pressures that would imposed on the building in the event of a full-scale hurricane. With Moore in attendance, wind-tunnel tests were undertaken on a one-eighth scale model of the Dome. Given that such a large project had never been attempted before, a number of industry professionals were on hand, including Ralph Anderson from the architectural firm of Wilson, Morris, Crain, and Anderson, along with Tom Kavanagh, a peer reviewer from New York City’s Praeger, Kavanagh, and Waterbury assigned to the project.7

The wind-tunnel tests were carried out using the aeronautical wind tunnels housed at the McDonnell-Douglas Aircraft Corporation facilities in St. Louis. Given that the Dome would have skylights permeating the surface of its roof, the model artificially represented these undulations via sand particles applied to the model’s roof with adhesives to simulate the roughness of the skylights during the wind-tunnel tests. In addition to outfitting the model with pressure points created by a series of pressure orifices, the team placed cotton tufts along the surface of the roof in order to visualize the wind’s varying effects upon the building.8

After the technical data was captured from the wind-tunnel tests, Herbert Beckman, a Rice University professor of nautical engineering, compiled and evaluated the results. In his September 29, 1961, report, Dr. Beckman observed that “during the tests, the model is subjected to a steady air stream while hurricane winds consist of small grain turbulence with a gust diameter of usually not more than 100 or 200 feet. These gusts will result in only partial loading of the building, and as a consequence, are less effective than a steady wind would be. The wind-tunnel data can be considered to give ‘conservative’ loads comparative with corresponding flow conditions in hurricanes.” As it turned out, the data proved to be remarkably close to the hand calculations made by Bass in advance of the wind-tunnel tests in Missouri.9

Having completed this phase of the project, Roof Structures assimilated the dome roof pressure contours obtained from the wind-tunnel tests into the firm’s design proposal for the lamella roof structure. Roof Structures accommodated the test results by incorporating different pressure bands across the graduated expanse of their roof design. Divided into five such bands, the pressure bands included segments designed to accommodate 20, 25, 30, 35, and 45 pounds per square foot, with the apex being able to withstand the highest level of pressure. Simply put, these graduated pressure bands served to contravene the suction pressure of hurricane-force winds attempting to lift the Dome away from its foundation.10

With Roof Structures having carried out the firm’s all-important work of testing the roof’s integrity, Zimmerman’s team at Walter P. Moore and Associates was left to ensure that the innovative roof structure was properly anchored to the rest of the building. This moment in the life of the Astrodome marked the design phase’s most significant instance in building the stadium to last. Perhaps most importantly, engineering integrity of the highest order was required in order to address a multitude of safety concerns. Roof Structures, whose success with the Dome led to the firm’s later work on the New Orleans Superdome, provided four drawings in support of a tension-ring design for the Astrodome. Working from Bass’s drawings, Zimmerman created diamond-shaped lamellas separated by ring structures, which doubled as the roof’s trusses. As a tension-ring formation, the Dome extended across the building’s supporting structure. Given the incredible forces and thoroughgoing tensions playing upon the design, the manner in which the Dome connected to the building proper was critical to its engineering.11

In order to accommodate the results of the wind-tunnel tests and the structural demands of Roof Structures’ tension-ring design, Zimmerman devised a pair of innovations – masterworks of engineering elegance that set the Astrodome apart from any long-span structure ever conceived. Christened by Zimmerman as the “knuckle” column and the “star” column, respectively, his deft approaches to addressing the wind-tunnel results and Roof Structures’ resulting proposal were nothing short of revolutionary. The knuckle column, Narendra K. Gosain observes, “was Mr. Zimmerman’s brainchild.” It was a “remarkable piece of engineering” based upon the human knuckle as a means for solving a complex problem: Simply put, how do you allow for movement toward the centroid or center of the Dome to account for temperature shifts, while deflecting movement of the structure caused by horizontal wind shear?12

To remedy this issue, Zimmerman devised a column that flexes, much like a person’s knuckle, toward the center, while remaining outwardly fixed. The knuckle columns exist along the stadium’s roofline, connecting the Dome itself to the exterior superstructure. Arranged circumferentially around the interior perimeter of the Dome every 5 degrees, the apparatus consists of four-foot-diameter steel pins at the end of each column. The lower bearing of each pin was welded to a plate support, leaving the top side of the pin to rotate freely in a close-fitted plate with a milled surface. If the top side had been welded, it would have been too rigid and in high wind conditions would have broken away from the structure, given the high tensions existing at that altitude of the building. In order to prevent uplift, anchorage was created at the top of each column via massive U-bolts. As long as the building exists, the knuckle columns will continue doing their work, acting in concert with temperature changes while remaining rigid in the face of enormous wind shear – flexing inward, yet not flexing outward, like the human knuckle.13 According to Gosain, when the Dome first opened, the knuckle columns at the top of the stadium were exposed, affording fans in the upper reaches of the stadium with a rare glimpse of engineering in action. Unfortunately, many visitors found the visible movement of the knuckle columns to be unsettling; hence, the joints were later concealed behind metal plates in order to prevent fan consternation at the sight of the Astrodome flexing in response to the elements.14

In addition to the knuckle column, Zimmerman utilized the innovation that he described as the star column, along with the concrete retaining wall at the Astrodome’s base, in order to execute Roof Structures’ tension-ring design. For Zimmerman, the star column and the retaining wall at the Dome’s lower perimeter afforded the massive building with two levels of tiebacks working in tandem with the knuckle column at the roofline. In engineering parlance, tiebacks act as anchors and stabilizing mechanisms in order to balance the heavy weight load of the roof – especially in a long-span structure such as the Astrodome – against the external forces working upon the building from horizontal and vertical vantage points. Zimmerman’s design called for two levels of tiebacks, including the star columns positioned at mid-height around the building’s exterior, as well as the tiebacks located every 5 degrees at the base of the retaining wall. The lower-level tiebacks were reinforced by a series of dead-man anchors, located 80 feet away from the retaining wall, in order to further support the efforts of the tension ring and preserve the building’s structural integrity. The building’s design criteria called for structural elements that protected the stadium against lateral wind loads and “people-generated sway loads.” In addition to concerns about numerous natural exterior forces, the structure had to withstand abrupt and rhythmic movements of personnel and visitors inside the building.15

For the most part, Zimmerman’s deployment of X-braced steel bents from the top of the stadium’s structure down to the foundation afforded the Astrodome with the requisite resistance to lateral wind loads working upon the building. Given the existence of expansion joints located around the stadium, each sector of the structure required its own system of lateral load-resistant frames. These midlevel tiebacks can be viewed on the building’s exterior as a series of distinctive star columns, located circumferentially around the Astrodome’s perimeter and positioned every 5 degrees. Zimmerman dubbed the features star columns, which resemble giant lower-case letter t’s. He coined the name to honor of the Lone Star State, Texas’s distinctive nickname in reference to its former existence as an independent republic. The tieback system was completed at the Dome’s lowest level by the tiebacks arranged around the base of the foundation as part of the retaining wall. The concrete that formed the retaining wall required a maximum strength of 3,000 pounds per square inch, with the perimeter retaining wall consisting of a counterfort system, which ties the building’s slab and base together. In this instance, the counterfort system serves as a buttress in order to provide rigidity and reduce the shear forces imposed on the retaining wall by the soil. The external tiebacks beyond the retaining wall consisted of steel strands placed every 2.5 degrees around the stadium. In order to protect the strands against the corrosive effects of the soil, Zimmerman’s design specified a cathodic protection system as a prophylactic measure. With such a system, the steel strands are protected by encasing them in a sacrificial metal, which serves as the anode of an electromechanical cell, while the steel strand that comprises each tieback acts as the cathode.16 Decades later, when unearthed for the purposes of renovation, the structural metal revealed no signs of corrosion during the intervening years, proving the original design to be highly effective.17

With the integrated design of redundant systems involving the knuckle columns, the star columns, the tiebacks, and the retaining wall in place, Zimmerman was able to satisfy, with great engineering elegance and innovation, the demands of Roof Structures’ tension-ring specifications.

As nearly 10,000 tons of steel began to arrive at the construction site, the contractor, American Bridge, started the process of overseeing the preparations for building the concrete retaining wall. In order to construct the Dome’s storied roof structure and connect it to the steel frameworks, crews from American Bridge fabricated 37 falsework erection towers. Each tower was placed circumferentially at the base of the building in order to provide support for the trusses that grew to span 642 feet in diameter. The towers consisted of an inner ring of 12 200-foot towers, an outer ring of 24 smaller 160-foot towers, and a 303-foot center tower. Thirty-six towers were arranged as opposing pairs in 12 pie sectors each of 30 degrees, with the 37th tower placed in the middle of the building in support of the Astrodome’s geometric center.18

The erection of the steel trusses presented particular challenges, as the tension ring had to remain vertical at 60 degrees Fahrenheit and with the dead loads applied in order to maintain the ring’s structural integrity. In order to accomplish this end, jacks were placed at the top of each tower to make incremental adjustments as the erection of the steel progressed.

Throughout the year, the project had become the focal point of local, national, and even international interest. While the media offered unremitting coverage of the building’s progress, Houstonians observed the ever-rising structure from vantage points across the city’s southern reaches. As the crews from American Bridge welded the trusses into place, the tension ring at the heart of the Dome’s structural design began to take form. Weighing 750 tons, the tension ring consisted of 72 steel sections of articulated joints in order to allow for the expansion and contraction of the roof.19

During the process of constructing the tension ring, Kiewitt strongly recommended that radiographs, similar to medical x-rays, be made of the welds in the tension ring in order to ensure that they were not cracking under the extreme weight of the building materials. Indeed, as the American Bridge crews worked to put all of the trusses and frameworks into place, a certain element of risk existed – and notwithstanding the extra protection and stability afforded by the erection towers – that a gale-force wind could topple the steel skeleton and injure the construction workers nearly 200 feet below. Kiewitt had clear reason to be concerned. During the summer of 1963, a high-force wind of 90 MPH had assaulted Victoria, Texas, some 125 miles to the southwest of the construction site. Anything along those lines would have spelled almost certain doom for Hofheinz’s lofty municipal dreams.20

Kiewitt’s insistence on regular radiograph tests may have made the difference in ensuring confidence in the incipient building’s structural integrity. As it happened, Hurricane Cindy pelted the Texas coastline with a steady assault of wind and rain in late September, and the frameworks, with all of its welds fully in place, withstood the onslaught with nary any damage.21 On December 2 the tension ring had finally been completed, along with the building’s support columns. As American Bridge crews anxiously watched, the jack on the central 37th tower was lowered and the tension ring rested atop its steel pillars. To commemorate the occasion, workers placed a pair of Colt .45 pennants atop the roof. Almost immediately, the stress of so much weight on top of the frameworks began to exert its awesome might, with 220,000 pounds of pressure being transferred onto the stadium’s support columns. Consequently, the columns bent slightly – and by as much as an inch in some places. To deflect the pressure, the American Bridge crews hastily erected temporary steel supports in order to deflect the load and protect the steel skeleton from suffering any damage. While the incident proved to be a momentary concern, it turned out to be a harbinger of other issues to come. As a result, engineering teams from Roof Structures and Walter P. Moore assembled in January 1964 and decided to cross-brace the columns to further enhance the structure’s support. As an additional measure, gamma ray equipment was deployed in order evaluate the quality of the welds before moving further with the project. As a result, 10 welds were found to be defective and subsequently corrected before construction continued.22

By early 1964, all of the Dome’s spans had been completed and the trusses and frameworks were fully in place. At this key juncture in the building’s construction – with the connections having been welded together and the alignment confirmed – the crews began the laborious and painstaking process of lowering the jacks and eventually removing the erection towers altogether.23 On January 16 Zimmerman announced that the columns were properly braced and could now support the roof structure without benefit of the erection towers. American Bridge predicted that it would take just under three weeks to lower the jacks and remove the towers.24 Concerns mounted as the trusses were released from the safety net afforded by the towers, and the integrity of Zimmerman’s engineering and design was ready to prove itself – or, failing that, to collapse on an international stage – branding Houston once more as a hick town in the watchful eyes of a waiting world.

Zimmerman had been known to joke with friends and family that if the structure were indeed going to founder, he wanted to be standing in the middle of the construction site, hundreds of feet below the centroid, to be spared the ultimate humiliation of seeing his work collapse in upon itself.25 But his gambit was hardly necessary. If Zimmerman truly held any doubts, they were resolved fairly quickly as the Dome’s skeleton held fast. On February 4 the roof was liberated from the erection towers, and the 7.5-million-pound lamella dome came to rest entirely on the stadium walls. After all of the towers had been removed, the stadium had sunk 4 inches, as predicted by the engineers, under the combined weight of the roof and the frameworks.26 For the first time, Hofheinz’s original vision of a modern-day Roman Colosseum was beginning to take form. The steel superstructure was finally complete, and the outline of the Astrodome’s interior frameworks remained visible for miles in every direction.

But as events would show, Houston’s collective sigh of relief over the building’s structural soundness was short-lived. With the steel frameworks in place, Zimmerman and his engineers tested the structure’s plumbness to see if it held true without benefit of the erection towers. And to their great consternation, and eventual panic, the mathematics didn’t add up. Simply put, the frameworks wasn’t plumb. In civil-engineering parlance, plumbness refers to a structure’s state of being vertical or “true.” Today, engineers test a building’s plumbness using laser equipment. In the Astrodome’s heyday, plumbness would have been tested by deploying a lead weight on the end of a line in order to determine verticality.

During the process of slowly retracting the jacks atop each of the 37 erection towers, Zimmerman’s engineering team periodically checked the tension-ring alignment and tested the plumbness of the columns. To their growing dismay, the plumbness results shifted on a daily basis. Not surprisingly, concerns began to mount among the engineers from Walter P. Moore and Roof Structures. Eventually, those concerns spread to the County Commissioners, who became increasingly nervous at the mere thought that such a high-profile project might prove to be structurally unsound after years of careful preparation and no-holds-barred politicking. Under this level of scrutiny, Zimmerman’s team reconsidered the monitoring data from the plumbness tests, while also examining the design of the supporting columns to ensure that nothing was amiss. Finding nothing of concern – save for the inconsistent plumbness data – Zimmerman gave the order to lower the jacks completely and release the frame to face the elements.27

Specifically, the team worked to ascertain the degree to which the columns’ deviation from plumbness remained constant from day to day. Specifically, the team worked to ascertain the degree to which the columns were out of plumb remained constant from day to day. Not only did the results not remain constant, but they varied daily. As the days continued to pass, tensions on the construction site mounted and the County Commissioners began to doubt the efficacy of the design. And then it finally happened: Zimmerman’s “Eureka!” moment when he discovered that the plumbness differential was due entirely to temperature effects. He realized that the columns needed to be checked at the same time on successive days in order to ensure that there were no variations in temperature. In short, the plumbness calculations would shift from morning to evening, as the frameworks moved from sunshine into shadow. Recognizing that his design allowed for temperature effects, Zimmerman exclaimed that “the old girl was behaving just as was predicted!”28

Zimmerman’s innovative design demonstrated the vital ways in which long-span structures like the Astrodome move almost continuously. The same effects can be understood in terms of high-rise buildings like the former World Trade Center in New York City, which was engineered with a certain degree of natural sway in concert with the elements – namely, wind – in order to protect both the engineering integrity and the Twin Towers’ occupants. As Gosain points out, “There is no structure that is rigid. They all move – all structures move. The wonderful thing that engineers have accomplished – and especially with such buildings as the World Trade Center or the Etihad Tower 5 in Abu Dhabi – is that they minimize structural movement so that it’s not perceptible.”29

Later calculations after the Astrodome’s completion confirmed Zimmerman’s hypothesis, as well as the soundness of his design. The engineers’ monitoring data demonstrated a temperature differential of 20 degrees Fahrenheit between the interior and the exterior of the building, but also the exterior from east to west, north to south. Yet another calculation proved that the Dome enjoyed a dead-load deflection of 1.88 inches. The fact that the Astrodome would be air-conditioned held the possibility of an interior/exterior temperature differential of more than 70 degrees Fahrenheit. Meanwhile, for the design’s wind load, the horizontal movement allowed for an incredible 5½ inches of sway. This posed a particular challenge for both the architects and engineers tasked with designing the expansion joint at the edge of the Dome’s roofline. The design specifications needed to be prepared for a total movement of 11 inches in order to account for 5½ inches in either direction. To remedy this issue, the design team devised a maintenance-free solution, which consisted of a screen appended to the tension ring and extending beyond a concrete curb on the edge of the stadium roof. The screen camouflaged the expansion joint, which was afforded with the requisite space to allow for total movement not to exceed 11 inches. Through this elegant solution, the screen and the curb overlap sufficiently to not allow the rain to blow into the building’s interior; at the same time, the curb’s height was designed to prevent rainwater from spilling downward from the edge of the roof.30

With the Dome’s plumbness crisis having been resolved, the project moved apace with slightly more than a year to go until Opening Day in the Astrodome in April 1965. By April 1, 1964, the crews began lodging the roof’s 4,596 skylights into place, with the concrete seat risers to be installed shortly thereafter.31 With the building’s skeleton having been fully completed, the project shifted toward the activities associated with fitting out any multipurpose stadium – although the Astrodome was hardly any run-of-the-mill sports complex.

As with Zimmerman and the team from Walter P. Moore, the project’s construction crews were especially enamored with the process of assembling and installing the Dome’s gigantic center-field scoreboard. Four stories high and 474 feet wide, the $2 million electronic scoreboard encompassed more than 50,000 individual light bulbs. Weighing more than 300 tons, the scoreboard, which would come to be known among sports fans as the “Home Run Spectacular,” required some 1,200 miles of wiring to become operational.32 As Gosain remarks, the scoreboard was designed, with Hofheinz’s typical bravado and brash showmanship, “to put the Aurora Borealis to shame!”33

The Astrodome’s gala opening on April 9, 1965, was punctuated by far more than Mickey Mantle’s home run for the visiting New York Yankees. It marked the birth, in many ways, of Space City, Houston’s long-sought recognition as a cutting-edge metropolis on a collision course with the twenty-first century. For pioneering engineers like Zimmerman, the Astrodome was, most assuredly, the highlight of his career, although he would be the first to admit that it was an engineering achievement to be shared by many, especially the building’s architects and the outstanding teams assembled by Roof Structures, American Bridge, and Walter P. Moore and Associates. Over the years he would be interviewed about the project. Invariably, Zimmerman would conclude his remarks by lapsing into a sentimental fondness. “It was the biggest and finest of its kind around,” he would say, thinking wistfully about his signal role in engineering what, for a time at least, some folks called the Eighth Wonder of the World.34

KENNETH WOMACK is dean of the Wayne D. McMurray School of Humanities and Social Sciences at Monmouth University, where he also serves as professor of English. He is the author or editor of numerous books, including Long and Winding Roads: The Evolving Artistry of the Beatles (2007), the Cambridge Companion to the Beatles (2009), and The Beatles Encyclopedia: Everything Fab Four (2014). Womack is also the author of three award-winning novels, John Doe No. 2 and the Dreamland Motel (2010), The Restaurant at the End of the World (2012), and Playing the Angel (2013). He serves as editor of Interdisciplinary Literary Studies: A Journal of Criticism and Theory, published by Penn State University Press, and as co-editor of the English Association’s Year’s Work in English Studies, published by Oxford University Press.

Notes

1 Lynwood Abram, “Kenneth E. Zimmerman, Helped Create Astrodome: Worked on Many Notable Projects during Long Career,” Houston Chronicle, December 24, 2008: B7.

2 “Dragline Rips into S. Main Stadium Site,” Houston Chronicle February 2, 1961, section 1, 1, 2.

3 Jason Bruce Chrystal, “The Taj Mahal of Sport: The Creation of the Houston Astrodome.” Ph.D. diss., Iowa State University, 2004, 226.

4 Interview with Narendra K. Gosain by Robert C. Trumpbour and Kenneth Womack on July 22, 2013, at Walter P. Moore and Associates, Houston, Texas. Note: Unless otherwise indicated, subsequent interviews with Dr. Gosain took place at the time, date, and location indicated above.

5 Kenneth E. Zimmerman and Narendra K. Gosain. “Astrodome: An Engineering Marvel of the 1960s,” Presented in the Texas Section of the Annual Meeting of the American Society of Civil Engineers, Houston, Texas, September 29-October 2, 2004, 4.

6 Interview with Narendra K. Gosain, 2013.

7 Interview with Narendra K. Gosain, 2013.

8 Interview with Narendra K. Gosain, 2013.

9 Interview with Narendra K. Gosain, 2013.

10 Interview with Narendra K. Gosain, 2013.

11 Zimmerman and Gosain, 4-5.

12 Interview with Narendra K. Gosain, 2013.

13 Zimmerman and Gosain, 7.

14 Interview with Narendra K. Gosain on July 22, 2013, in the NRG Astrodome, Houston, Texas.

15 Zimmerman and Gosain, 7.

16 Zimmerman and Gosain, 8-9.

17 Interview with Narendra K. Gosain, 2013.

18 Chrystal, 231-32.

19 Chrystal, 233-35.

20 Chrystal, 233-35.

21 Chrystal, 236.

22 Chrystal, 239-40.

23 Zimmerman and Gosain, 6.

24 Chrystal, 242.

25 Correspondence from Fred Womack to the authors, April 30, 2015.

26 Chrystal, 243.

27 Zimmerman and Gosain, 6.

28 Zimmerman and Gosain, 6.

29 Interview with Narendra K. Gosain, 2013.

30 Zimmerman and Gosain, 6-7.

31 Chrystal, 243-44.

32 Chrystal, 276.

33 Interview with Narendra K. Gosain, 2013.

34 Abram.